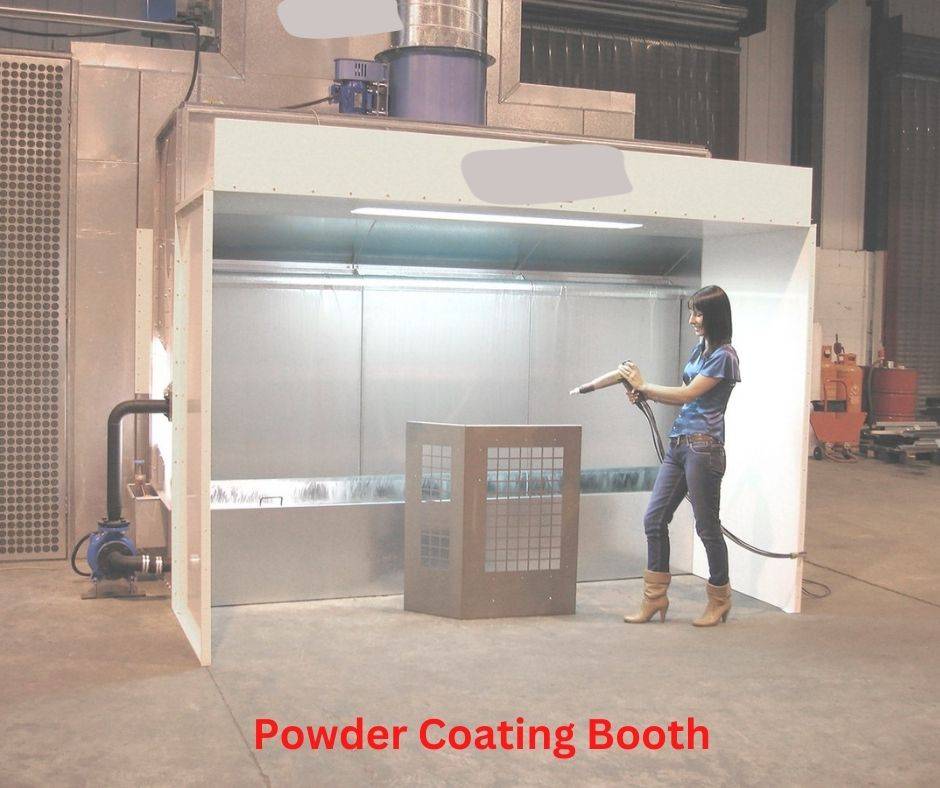

Powder coating is a process that coats objects with a layer of paint that is applied through pressing, spraying, or brushing. Powder coating booths come in different sizes and can be used for a variety of applications, such as automotive, industrial, and medical. By using a powder coating booth, you can improve workflow and quality control, as well as reduce costs associated with the production process.

The Application Process for Powder Coating in powder coating booths: How does the application process work with booths?

Powder coating booths are an essential part of any powder coating operation. They help to regulate the process and keep the equipment in good condition. The application process for powder coating usually begins with a rough surface area preparation. This is usually done with a wire brush or sandpaper. The surface is then treated with a primer or sealant to protect it from oxidation and other environmental factors.

The next step is to apply the paint, which will be done in layers using a “drop” technique. After each drop has been applied, the booth is rotated so that the next layer can be deposited on top of the previous one. When all of the layers have been applied, the finish coat is applied and then polished out.

There are many factors that must be considered when applying powder coatings, including temperature, humidity, and air pressure.

How helpful is a powder coating booth to your business?

Powder coating booths are a valuable tool for businesses of all sizes. They can help you quickly and easily coat products with a durable finish. In addition, powder-coating booths can be customized to fit your needs. Whether you need a small 8x8x10 booth or a larger 10x10x10 booth, there is a perfect option available. When you choose a powder coating booth from Reliant Finishing Systems, you know that you’re getting quality equipment that will help your business grow.

What is needed to operate a powder coating booth?

Operating a powder coating booth is not difficult, but it does require some preparation. A basic powder coating booth needs a spacious area available for larger parts. The area must be clean and free of any obstacles. Tables and chairs should be placed in strategic positions to allow the operator to move around easily. Other necessary equipment includes a supply of sandpaper, primer, paint and coatings, ladders, and workstations.

What are the benefits of using a powder coating booth?

Powder coating is the process of applying a thin layer of powder to a surface, then heating the powder until it liquefies and sticks to the surface. The powder coating process provides a number of benefits over other coatings, including a high level of accuracy and durability.

One key benefit of using a powder coating booth is accuracy. Powder coating can be difficult to apply evenly, and this can lead to inconsistencies in the final product. By using a booth that is 8x8x10 or 10x10x10 powder coating booth, you can ensure that your parts are accurate and consistent from part to part.

Another key benefit of using a powder coating booth is durability. Powder coatings are typically very thin layers, so they’re less likely to wear down than more traditional coatings.

Conclusion

A powder coating booth can be a great investment for any powder coating business. By providing a quality and consistent finish, the booth can help your company stand out from the competition. If you are considering adding a booth to your business, be sure to consider all of the benefits it may provide.

Read more: How Can You Improve Your Retail Customer’s Queuing Experience?