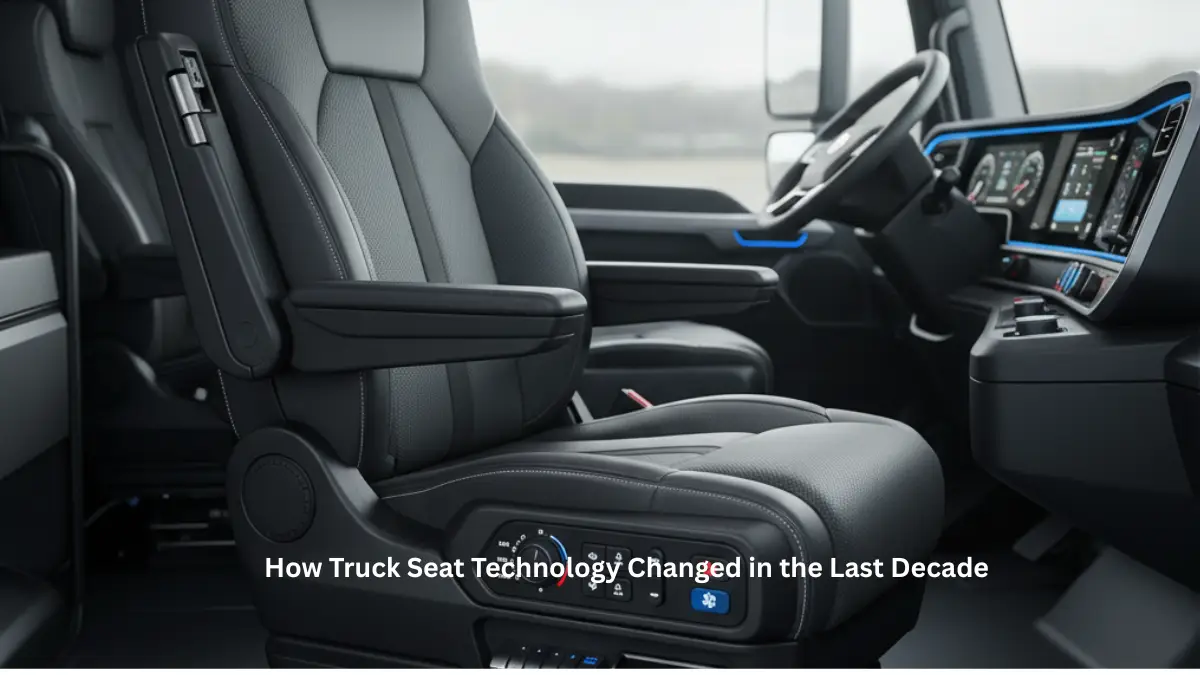

Ten years ago, the average truck seat was semi-padded with maybe some adjustable lumbar support. Today, the distinction is almost night and day. All of the technology packed into modern truck seating would have seemed like something out of a sci-fi film back in 2015, and operators who’ve upgraded from older models to new models know it immediately.

What Actually Changes Beneath the Surface

The greatest change came in terms of suspension systems. Old school seats operated with somewhat basic spring technology that operated to a lesser extent as shock absorbers. They performed well enough on paved highways but failed miserably on potholes or job sites. Today, air suspension is something entirely different, constantly adapting in real-time with varying weight, terrain, and driving conditions.

Interestingly enough, the materials shifted, too. Memory foam found its way into commercial seating as it became more advanced, but it’s not the same memory foam you find at the mattress store. This memory foam and its variants are tempered for extensive temperature changes, constant movement, and extreme wear-and-tear from everyday commercial use for years on end. Some companies even used gel layers and ventilated foam that actively works against heat development on long drives in the summer.

The frame construction became smarter, too. Instead of weld this here and there with a praying hope it will last longer than a year, engineering schematics relied upon computer-generated models to determine where stress fractures might occur over time. This led to added reinforcement in key areas and lightweight composite materials in others. Replacement truck seats for sale now boast this new technology for operators who wish to repair worn seats who never had the option in older commercial vehicles.

The Control Panel Revolution

While it may seem miniscule, the adjustment systems for drivers to set their seats became much easier over time. Manual levers that required decent muscle to heave have become few and far between. Pneumatics control basically everywhere allows slight adjustments with minimal effort on behalf of drivers. Certain higher-end models even brought in electronic adjustments with memory settings.

Drivers avoided adjusting their seating thanks to frustrations from older systems. If it meant stopping the vehicle, maneuvering themselves awkwardly to wrestle with a stubborn lever, most people would just tolerate discomfort. Easier systems meant people actually utilized them, which made comfort that much better.

Vibration Isolation Gets Serious

One of the features that adjusted over time was vibration dampening. Older, less technologically advanced truck seats passed much vibration from the engine or the road right through to drivers. Over time, this constant low-level vibration creates serious problems. Whole-body vibration isn’t just annoying; it’s related to long-term health impacts developed over the last few years.

Advanced truck seats boast three-stage isolation systems: primary suspension, secondary dampening layers, and sometimes tertiary systems in high-end vehicles. These systems operate independently based on vibration frequency levels. The result is significantly less fatigue at the end of a long shift for operators in contemporary trucks versus those who spent the day in equipment made years ago.

Smart Features Start Showing Up

Around mid-decade 2010-2020, some manufacturers took it an extra mile with features that felt almost unnecessary. Heated and cooled seats emerged from luxury cars into work trucks. While climate control sounds unnecessary for a work setting, those who have it say it’s hard to stay focused when flustered by extreme weather conditions.

Weight sensing improved as well. Instead of relying upon manual adjustments for driver weight, impacted suspension settings one way or another, seats automatically compensated. That makes a difference more than it might sound because improper suspension conditions do make comfort less comfortable.

Materials That Actually Last

The upholstery itself saw a lot of upgrade changes. Cracked and torn vinyl occurred within a few years from constant use and sun exposure. New synthetic options are better UV resistant and capable of temperature extremes without breaking down as fast over time. Some fabrics even boast antimicrobial technology for those shared or fleet vehicles.

Stitching saw improvements, too. The weak point in most older vehicles sat at where seams split under stress. Modern construction spreads tension more evenly across the truck seating for failure points to occur less often.

What This Means For Operators Today

The practical implementation proves how much things changed today versus ten years prior. Drivers who replace truck seats for units created in 2015 or earlier believe they’ve upgraded to a different class of vehicle altogether thanks to decreased soreness and fatigue at the end of every shift.

For fleet managers, it’s been cost prohibitive in contemporary times, too, modern costs exceed basic costs ten years ago, but extended longevity on modern truck seating offers improvements worth serious consideration for driver retention purposes in such challenging times to find and keep qualified drivers. Equipment that makes their lives more tolerable works as a competitive advantage when no one has them.

It gets even better; technology is advancing still. Current developments seek biometric feedback, posture correction systems and improved vibration isolation measures. What seems advanced today will probably seem basic in another decade’s time; however, anyone operating older equipment should know these advancements have made strides towards operator comfort like never before benefiting this population long-term health-wise.